Over the last ten years, the transformation in the healthcare and wellness sector in India has been nothing short of phenomenal. With growing consumer awareness of preventive health and holistic wellness, there are unparalleled opportunities for quality healthcare products that ensure both efficacy and safety. It is not just a market trend-the way Indians approach health and well-being is fundamentally changing.

The manufacturing landscape has totally changed for healthcare products, driven by strict regulatory frameworks, advancing technology, and increasingly sophisticated consumer expectations. Indeed, companies that thrive in this environment are those able to balance traditional wisdom with modern scientific validation in a manner that ensures the highest standards of quality control and safety protocols.

Manufacturing Excellence in Healthcare Product Development

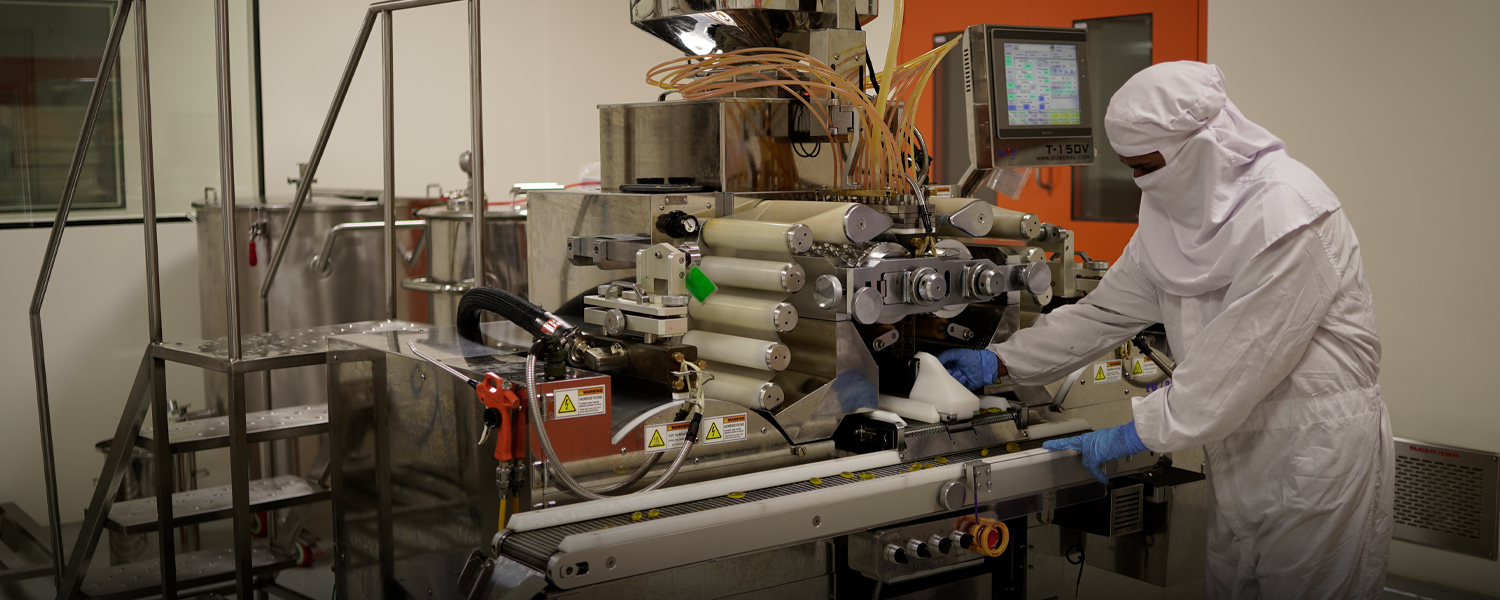

Manufacturing healthcare and wellness products is multi-faceted, ranging well beyond the capabilities of a basic manufacturing facility. To be considered acceptable for major clients, facilities have to maintain GMP standards of operation, adhere to rigorous quality assurance protocols at every production stage, and document everything accordingly. This level of scrutiny ensures that every product reaching consumers meets predetermined specifications for purity, potency, and safety.

Modern manufacturing units are fitted with the most advanced equipment for the production of a wide range of formulation types. The technical diversity required for producing formulations in capsules in hard gelatin and soft gelatin forms-tablets, powders, and liquid oral presentations is great. Advanced facilities also enable the production of specialized formats such as diskettes, biscuits, bars, and functional foods, each with specific processing techniques and quality parameters.

The integration of automated systems with human expertise means that precision and consistency are achievable standards and not just aspirational goals. Temperature-controlled environments, contamination-free zones, and validated processes ensure that batch-to-batch variation stays as minimal as possible critical factor in maintaining product reliability.

The Rise of Herbal and Nutraceutical Formulations

The rich heritage of traditional medicine systems, like Ayurveda, places India in a privileged position within the global wellness market. As a herbal supplement manufacturer in India, firms are increasingly bridging the gap between ancient botanical knowledge and contemporary scientific research. Such a synthesis assures products that offer the therapeutic benefits of time-tested herbs while meeting modern standards of standardization and bioavailability.

Herbal formulations require specialized expertise in botanical sourcing, extraction methodologies, and standardization techniques. The active compounds of plant materials may be highly variable depending on cultivation practices, timing of harvests, and methods of processing.

Sophisticated manufacturers have stringent supplier qualification processes and raw material testing to assure the consistency of the phytochemical profile of their herbal ingredients.

The nutraceutical market, in particular, has been one of the strongest growth segments because of consumers looking to prevent, rather than just treat. Such nutritional supplements falling squarely between nutrition and pharmaceuticals have to be well-formulated to deliver both clinically relevant dosages of active ingredients and also remain palatable and stable.

Solutions for Custom Manufacturing and Brand Development

The manufacturing of health products has moved significantly towards customized contracts. The private label nutraceuticals form a strategic route for the brands that want to enter the wellness market or establish themselves in the space without making any investments in the manufacturing infrastructure. The model allows companies to focus on brand building, marketing, and distribution while leveraging the technical expertise and production capabilities of established manufacturers.

Some of the major strategic advantages of private label arrangements are access to proven formulations, which have been stability-tested and approved by regulators-activities that bring down the time-to-market. Economies of scale in raw material purchases and expertise in production efficiency are both hard to achieve by a single firm on its own. Besides, third-party manufacturers contribute their experience in managing regulatory matters of great importance to the brands.

Manufacturers offering private-label services present value propositions well beyond production capacity. This would include formulation development support, regulatory guidance, packaging design consultation, and often even assistance with market positioning. This relationship becomes collaborative, with the manufacturer acting as a technical partner rather than a simple supplier.

Quality Assurance and Regulatory Compliance

The manufacturing sector of healthcare operates within the ambit of strict regulatory controls that are put in place to safeguard consumer safety. Central organizations, such as the Food Safety and Standards Authority of India and the Central Drugs Standard Control Organization, lay out frameworks relating to product formulations, manufacturing practices, labeling requirements, and safety standards.

All of these regulations demand thorough quality management systems that must document and verify every single aspect of production: from the qualification of suppliers and the testing of raw materials to in-process controls and analyses of the final products, everything has to be validated and recorded.

Manufacturers should maintain detailed batch records for complete traceability in case of any quality issues arising post-market.

Advanced facilities implement additional quality measures beyond the minimum regulatory requirements. These may involve accelerated stability studies, microbial testing at various stages in production, and using advanced analytical equipment such as HPLC to verify raw ingredients and ensure potency.

Third-party certifications and audits are an added assurance of quality in manufacturing. International standards, such as ISO certifications, reflect a commitment to quality management that finds acceptance both in the domestic and export markets. Such credentials become particularly important for companies desiring to expand their presence in regulated international markets.

Innovation in Product Formats and Delivery Systems

Consumer preferences continue to evolve, pushing the envelope in product formats and delivery mechanisms. Whereas traditional tablets and capsules remain prevalent, increasingly sophisticated alternatives are being developed that address specific consumer needs or preferences.

Soft gelatin capsules, for example, have particular advantages for oil-soluble nutrients and botanicals, offering better bioavailability compared to more traditional formats. Liquid formulations and powders are attractive to those who prefer flexible dosing or cannot swallow solid dosage formats easily. Functional foods-fortified biscuits, nutrition bars, and beverage mixes-are incorporating wellness benefits into more familiar patterns of consumption.

These various formats require specialized equipment and technical expertise to develop. Each delivery system poses unique challenges with regard to ingredient compatibility, stability considerations, and manufacturing processes. Companies that successfully master multiple formats are better positioned to serve a wide variety of market segments.

Advantages of Strategic Location and Infrastructure

First and foremost, geographic positioning plays a vital role in manufacturing efficiency and market access. Central locations with robust transportation infrastructure facilitate both raw material procurement and finished product distribution. Proximity to ingredient suppliers reduces logistics costs and lead times, while connectivity to major markets enables responsive supply chain management.

Manufacturing facilities in established industrial hubs enjoy not only access to skilled technical manpower but also supporting industries and an established regulatory ecosystem. Utilities infrastructure—reliable power supply, water treatment facilities, and waste management systems—that is necessary for uninterrupted manufacturing operations often characterizes these locations.

This is the reason for knowledge clusters, where expertise builds up, and best practices spread rapidly in these regions. This form of collaboration, even among competitors, tends to raise the standards for the industry and, as a result, fosters improvement in manufacturing capabilities.

Future Perspectives in Healthcare Manufacturing

The healthcare manufacturing sector is at an inflection point, wherein a number of trends are going to reshape the industry’s landscape. Nutrigenomics and diagnostic testing are two areas where advancement is leading to more personalized nutrition with targeted supplementation. In this emerging paradigm, manufacturers who can accommodate smaller batch sizes with greater product variety will be well-placed.

Sustainability considerations are increasingly driving manufacturing decisions, from ingredient sourcing to packaging choices. Consumers are not only scrutinizing the efficacy of products but also the environmental footprint of their wellness choices. Forward-thinking manufacturers are committed to green chemistry principles that reduce the generation of waste and explore biodegradable alternatives for packaging.

Digital integration is shifting the paradigms toward better quality management and operational efficiency. Real-time monitoring systems, predictive maintenance algorithms, and automated documentation further increase consistency with lower human error. Blockchain is being assessed for supply chain transparency to help consumers trace the origins of ingredients and their manufacturing provenance.

Conclusion

Over the years, the healthcare manufacturing sector has evolved to become sophisticated in the country and is well-equipped to offer quality products in a range of categories. Success in this space requires more than just manufacturing capability-it demands a deep understanding of regulatory needs, quality systems, market dynamics, and consumer expectations.

As the wellness market continues its upward trajectory, manufacturers who combine technical excellence with flexibility, innovation, and unwavering commitment to quality will define the industry’s future. The integration of traditional botanical knowledge with modern manufacturing science positions India uniquely in serving both domestic and global wellness markets, creating opportunities for companies prepared to meet the sector’s exacting standards.

Partner with excellence. Launch your branded supplements today.

India’s trusted CDMO Partner, delivering science-driven solutions across healthcare & cosmetics sectors.

© 2026 H&H Healthcare and Cosmetics Pvt. Ltd. Designed by ROI Makers.